Applications

Dado lab designs and manufactures isokinetic sampling lines dedicated to the determination of particulate matter, and micropollutants as well, in stack emission.

Our solutions are designed to meet and exceed the requirements of EN and EPA methods but also features smart solutions to make easier the most difficult sampling operation.

A combustion is a very dynamic and complicated physical, but also chemical, process taking place at conditions which will dramatically change from the origin point to the final emission into the atmosphere...

A combustion is a very dynamic and complicated physical, but also chemical, process taking place at conditions which will dramatically change from the origin point to the final emission into the atmosphere...

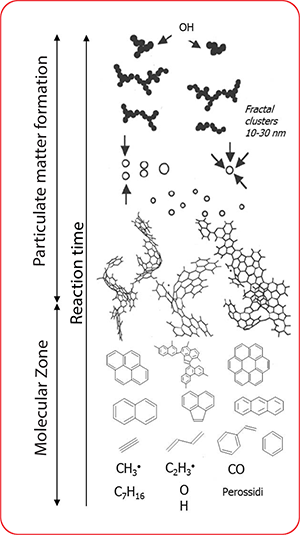

The oxidation of the combustible generates the precursors of the soot but then, due to the generated differential pressure caused by the heat of the process, those precursors move along the stack where the conditions of absolute pressure and temperature may vary very quickly.

Those variations start different processes, from formation of complex hydrocarbons, polimerization and then nucleation, where those heavy molecules combine together forming the first particles.

This surface growth process continues and other molecules, present in the gas phase, are adsorbed and trapped inside the agglomerating particles.

Along the stack emission path, particles collides starting the coagulation process, generating bigger particles and, finally, clusters of particles.

Clearly the particulate matter and, many, chemical compounds are strictly connected and the isokinetic sampling is necessary also for determination of those chemical species.

Due to the chemical characteristics of those compounds, a unique solution for their capture and determination is not possible. Depending on the micropollutant we have to evaluate, different methods asking for different solutions are available.

Beside methods describing how to properly carry out an isokinetic sampling, there are also other methods defining the procedures and devices to determine water content, density, flue gas velocity or the sampling grid and other aspects. Those methods are:

EN16911 Manual and automatic determination of velocity and volume flow rate in ducts

EN14790 Determination of the water vapour in ducts

EN15259 Measurement of stationary source emissions

EPA M1 Sample/Velocity Traverses

EPA M2 Determination of Stack Gas Velocity and Volumetric Flow Rate

EPA M3 Determination of Dry Molecular Weight

EPA M4 Moisture Content

The isokinetic condition

When sampling particulate matter from a stationary source it is important to respect the isokinetic condition.

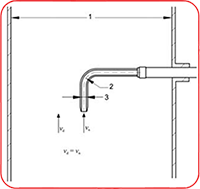

We are in isokinetism when the flue gas velocity travelling along the duct (vd) is equal to the flue gas velocity entering the sampling line through the nozzle (vn).

1) duct

1) duct

2) Radius of the bend (min. 1,5i)

3) Internal diameter i

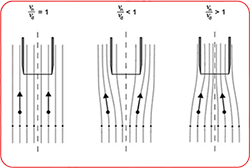

When the above condition is not met, then we may have the hypokinetic or the hypokinetism condition.

In particular, when Vn ‹ Vd, we are in hypokinetism and the particles are dragged inside the nozzle because of the "sling effect" due to the flow stream deviation.

In particular, when Vn ‹ Vd, we are in hypokinetism and the particles are dragged inside the nozzle because of the "sling effect" due to the flow stream deviation.

For the same effect, when Vn › Vd, the particles are thrown out of the stream and do not enter the nozzle.

The above situations result in a over or underestimation of the mass concentration mainly in relation to the particulate matter size distribution.

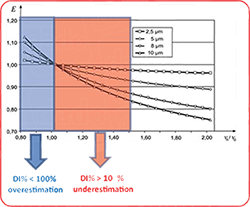

The deviation from the isokinetic condition affects particles with aerodynamic diameter greater than 2.5 um.

The deviation from the isokinetic condition affects particles with aerodynamic diameter greater than 2.5 um.

Since the weight of the particles increases esponentially with the diameter, the lost of bigger particles will result cause an increase of the errors.

Particulate Matter Instack

Particulate Matter Outstack

Furans Dioxines

Metals

Mercury

Chlorides

Dado Lab Srl

Via Pellizza da Volpedo 101A,

20092 Cinisello B. (MI)

tel. +39 02 36569420

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

R.E.A. MI n°2062810

Capitale Sociale € 50.000,00 I.V.

P.IVA 08356080963

Dado Lab Srl

Via Pellizza da Volpedo 101A,

20092 Cinisello B. (MI)

tel. +39 02 36569420

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

R.E.A. MI n°2062810

Capitale Sociale € 50.000,00 I.V.

P.IVA 08356080963

Dado Lab Srl

Via Pellizza da Volpedo 101A,

20092 Cinisello B. (MI)

tel. +39 02 36569420

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

R.E.A. MI n°2062810

Capitale Sociale € 50.000,00 I.V.

P.IVA 08356080963